Product Development / Design Engineering

Vision. Mission. Success.

Entrust your ideas to our experienced specialists, benefit from our clever minds and the knowledge resulting from our +70 years of company history. We will accompany you as your competent development partner, from the idea to series production. Our services include for example:

- technical advice and assistance from the beginning

- assistance in the search for innovative solutions by using state-of-the-art development and manufacturing technologies

- the advantage of long-standing expertise in solution-oriented and results-driven approaches

Tell us what you expect from your product. We understand your demands and use our long-standing experience to find a customised, plastic-specific solution together with you. We will support you during the design of the article and advise you on the selection of suitable materials.

As early as during the planning phase, cutting-edge data exchange interfaces enable a smooth data transfer between you, our design engineers and our tool making department. This results in direct advantages, such as cost and time savings.

Our competent and trained contacts will be happy to help you with your individual enquiry. You know your requirements and quality criteria, and we will be happy to help you implement them.

Tool Making

Tool making – customised, efficient and safe

Every day, we work in a two-shift system on around 800 square metres to implement your tool orders efficiently and on time. Safely stored and protected against fire and damages, a total of 150 tools are created every year. We guarantee you short production times and support you in the manufacture of your individual tool.

Do you need a tool? We can bring your wish into shape.

Plastics Manufacturing

Modern plastics production - quantity plus quality

Our production merges large capacities with extraordinarily high quality. We are currently working with 40 modern injection moulding machines which are mostly equipped with robots and removal grippers. This guarantees smooth and cost-effective production processes. Articles with injection weights from 1 g to 1,000 g as well as injection moulding machines with clamping forces of up to 5,000 KN emphasise our enormous production range which is further supplemented by multi-component and multi-colour injection moulding as well as by co-injection moulding processes.

We are already manufacturing more than 8,000 plastic articles of all kinds, from small series to large quantities. Furthermore, we have a very comprehensive range of materials at our disposal. It covers everything from standard materials to high-tech requirements. A central material supply with material drying is the starting point for all subsequent, automated production processes. Continuous optimisations in all production processes, targeted material inspections, glow wire testing and documented measurements by our trained employees guarantee high-quality products.

Thanks to our membership in the Kunststoff-Institut Lüdenscheid (Lüdenscheid Plastics Institute), we have active access to the latest plastics-related information and processing methods. This knowledge brings us up to date with the latest technologies.

Post-Processing

Post-processing – perfection as a benchmark for success

Benefit from our comprehensive range of post-processing services, such as:

- Fitting of complex assemblies

- Ultrasonic welding

- Heat embossing

- Metallization

Our qualified partners also assist you in:

- Metallising

- Coating

- Galvanising

- Digital printing

Quality Assurance

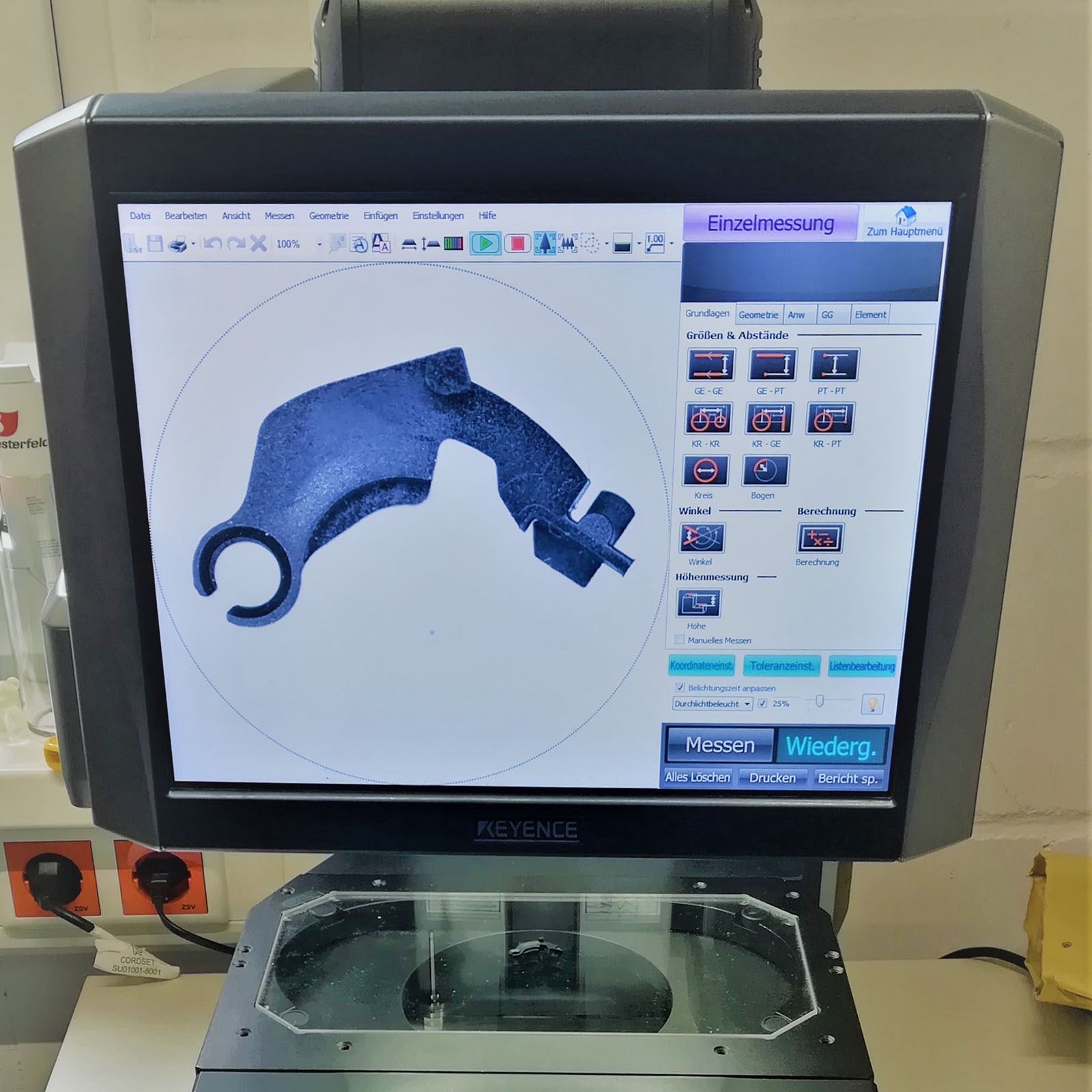

Quality is not a matter of course, but the result of accuracy. Our long company history proves that we are able to score in this area. Every day our quality assurance department checks the manufactured products for precision and dimensional accuracy.

Besides, an annual audit is carried out to check and, if required, optimise our production processes.

Logistics

A good address - also when it comes to logistics

Sufficient storage space and an efficient organisation are decisive factors when it comes to guaranteeing minimised costs and high reaction speeds. Built in 2017, our new logistics hall offers 2,500 m² and more than 3,000 pallet spaces for storing your articles. We use all types of shipping methods and operate in a cross-system and timely manner on both national and international markets. You can rest assured that you will receive your products with needs-based and, upon request, just-in-time deliveries.